Our team is here to support you and solve your power challenges. Connect with our responsive experts today to learn about our customized power solutions and products.

Roof Top Mounted Load Banks

Trystar is a leading manufacturer of high-capacity Load Banks. The LD-RT Series of Radiator Duct Mounted Load Banks offers simple, easy to mount, economical solution for providing diesel generators with a supplemental load to minimize the effects of wet-stacking during operation under lightly loaded conditions. Trystar is setting the standard with intelligent operator controls, safety indication layouts, and adjustable load step resolution. The LD-RT Series of duct mounted load banks provides a cost-effective solution for regularly scheduled maintenance testing of mission-critical standby emergency power generators.

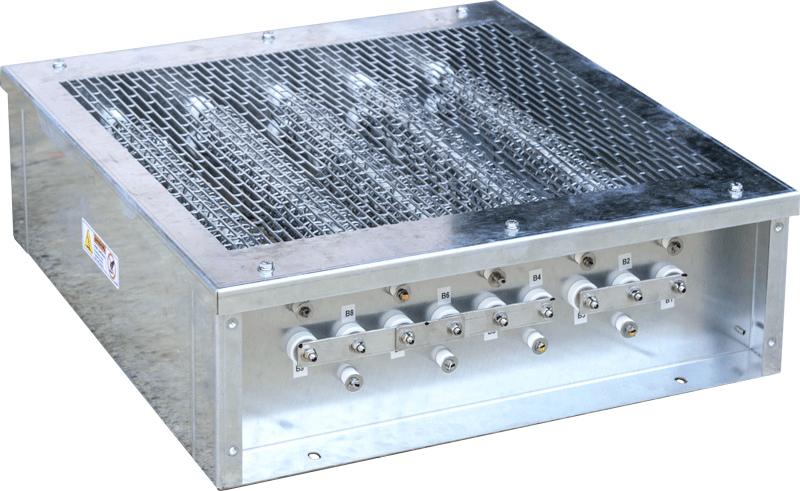

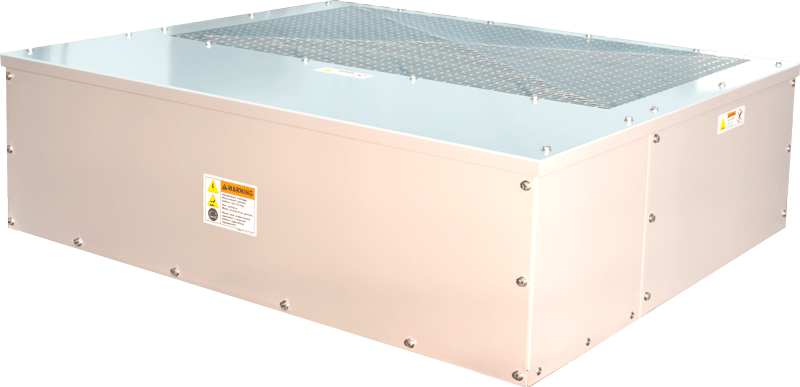

Built to Last Construction

LD-RT Series of roof mounted load banks come standard with powder-coated galvanized steel frames, stainless steel tops and stainless steel hardware. Don’t settle for unpainted frames or pay a premium for a powder coated enclosure.

The roof top frame is sized to match the exhaust opening and can be designed to provide an overhang for convenient bottom conduit entry. The frame houses the resistor load elements as well as an integral side-enclosure for customer load connections, load step contactors, controls and fusing. The operator controls are provided in a separate NEMA 4 enclosure for remote installation.

Operator Controls

- Illuminated Main Power On/Off switch

- Master Load On/Off switch

- Individual Load Step Switches

- Fault condition smart indicators provide operator display and load disconnect during Overtemperature, and Load Dump

Operator Protection

LD-RT Series Load Banks comes equipped with an Operator Control Panel. The Emergency-Stop push button allows the operator to take the unit off-line should a critical hard-stop condition occur. Branch circuit fuse protection provides short-circuit fault protection of all load steps eliminating the potential for catastrophic failure. Over-temperature circuits disable all load steps during a fault condition with illuminated indicator. The Load Dump circuit provides the operator visual indication if all load steps have been removed.

Automatic Load Level Control

Engine Wet-Stacking Solved. Trystar’s optional Load Level Control provides automatic load regulation by sensing the downstream connected load and adjusting the amount of supplemental load bank steps applied.

PowerDyne™ Load Elements

PowerDyne™ Resistors are the most rugged in the industry. They are fully supported across their entire length within the air stream by stainless steel support rods which are insulated with heavy-duty, high-temperature ceramic insulators. Change in resistance is minimized by maintaining conservative resistor designs.

KW Load Capacity

The LD-RT Series of roof top load banks is available in any size range from 10 KW through 400 KW at any available single phase and three phase Voltage (up to 600 Volts AC). They are intended for use as a supplemental load to the generator set and are typically sized at 50% of the generator KW rating.

Automatic Load Dump

The Automatic Load Dump circuit provides user interface provisions to the generator controls, automatic transfer switch, or building management system, to disconnect and disable all load steps from a normally closed (NC) set of auxiliary contacts. In the event of an actual power failure, all load bank load is removed from the source under test.

Remote Indication and Alarm

The Remote Indication and Alarm contact closure [form-c-type normally open and normally closed] provides user interface to your building management system for indication, detection, and alarm of “Over-Temperature”, and “Load Dump”.

Product Specifications

Main Features

- Specifically designed for rooftop mounting on a sound attenuated GenSet enclosure with vertical exhaust

- Reduce engine wet-stacking | Improve engine emissions

- Sized to match exhaust area

- Separate wall mounted Operator Control Panel

- Outdoor weatherproof construction. Roof Top resistor frame is galvanized steel with powder-coat paint finish, stainless steel fasteners and exhaust screen.

- Custom paint colors to match GenSet enclosure

Power Rating

up to 400kW

System Voltages

up to 600 VAC

System Frequencies

50 or 60Hz