In today’s energy-reliant age, facilities that use emergency backup generators to run mission-critical business operations or life support rely on load bank testing to ensure their power source output capabilities. Know for short as gen-sets, electrical generator sets must maintain system functioning off the grid and kick-start seamlessly after an overall power failure.

Radiator-mounted load banks are an efficient way to test and support diesel generator power output, ensuring your emergency power source runs smoothly. If your facility is considering specifying a radiator-mounted load bank, there are a few considerations to keep in mind.

What Is a Radiator-Mounted Load Bank?

Radiator-mounted load banks are load banks attached to the radiator on a diesel gen-set. The generator engine fans provide the necessary cooling air to the load bank’s resistor elements, keeping the system and exhaust temperature at the optimum level. Radiator-mounted load banks are mounted to the front or inside walls of the generator rather than standing separately in another space, as with other types of load banks.

Some radiator-mounted load banks are also attached to the generator roof, allowing horizontal design and space-saving installation. This design gives radiator-mounted load banks a smaller footprint than other types of load banks. Load banks mounted on the generator unit are a good option for facilities that want to save space.

Routine testing of gen-sets is effective at ensuring and maintaining maximum generator capacity. These units can be also be used with generators that require supplemental power to operate at peak efficiency. Radiator-mounted load banks offer an efficient solution to minimizing the effects of wet stacking during lightly loaded generator operation.

Radiator-mounted load banks are intended to be used as a supplemental load to the power source, so they typically supply around 50% of the generator’s kilowatt rating. Radiator-mounted load banks come in sizes from 10 kilowatts to 1,000 kilowatts and can fit various generator sizes. Determining your facility’s generator kilowatt rating helps you determine your load bank’s power needs, as facility testers must apply a load within the generator-rated capacity during load testing.

Why Should You Get a Radiator-Mounted Load Bank?

When picking a load bank for your facility, consider your facility’s energy needs, available space and the benefits of each type of load bank. Radiator-mounted load banks are an excellent choice for routine power source testing because their design provides several advantages when compared to other load banks.

The four main types of load banks include stationary, portable, radiator-mounted and trailer-mounted units. Of these four, only radiator-mounted units are attached to the generator — the others are free-standing and self-contained. In addition, radiator-mounted load banks rely on the diesel generator for cooling and placement, so they operate on generators with a unit-mounted radiator. These units are easy to install and can be placed in various locations on the generator.

The benefits of specifying a radiator-mounted load bank include:

1. Versatile Placement

Radiator-mounted load bank units have the distinct advantage of being adaptable in their placement because of their simple design. These units can be mounted on the inside, outside or roof of the gen-set unit. If needed, radiator duct-mounted load banks can also be installed within the duct framework, as long as they have essential cooling air.

Radiator-mounted load banks generally have a smaller footprint than portable or stationary load bank designs since they are mounted to the generator’s radiator and are limited by the radiator’s size. Provided your facility has enough room outside for this installation, this can save space that bulkier load banks would otherwise use.

2. Easy to Install

Mounting a load bank to a radiator is simple. These units are attached with stainless steel hardware to the gen-set enclosure in the path of the radiator’s exhaust airflow. Mounting a load bank on a generator radiator allows great versatility, as these load banks provide flexible and compact installation. They can mount directly to the radiator, within an air duct or to an indoor wall.

Depending on the placement of your generator, a radiator-mounted load bank could also be mounted onto the building’s exterior wall, where there is an exhaust opening between the generator and the engine room wall.

Such versatile installation allows variety in your facility’s load bank design. The only limiting factor in installation is the required size of the load bank compared to the generator, as the load bank mus meet a specific load capacity. If installation within the generator walls is impractical, roof mounting is a standard solution.

3. Economical

Compared to other load banks, radiator-mounted load banks are often more cost-effective solutions to routine generator power testing. The cost-effectiveness of these units is primarily due to their compacted size. These load banks require no cooling fans or other components. Instead, the engine fans produce the air that cools the load bank. Load bank mounting on a radiator eliminates the need for another fan, motor, motor controls or motor starters.

Radiator-Mounted Load Bank Features

To effectively test power source output, radiator-mounted load banks come with several performance and safety features. These features help the system continue operation in case of a part malfunction or power loss, increase efficiency and ensure operator safety. Some standard radiator-mounted load bank features include:

- Separate controls: The operator control components should be electrically isolated from the load elements so that the operator can still access the controls in any situation. The operator controls are unit-mounted or remote-mounted. Along with illuminated Main Power and Main Load on/off switches, the operator controls include individual load step switches for fine-tuned load testing. In addition, fault connection indicators maintain the operator display and load disconnect during over-temperature.

- Operator safety features: The operator control panel also features an emergency stop button the operator can use to perform a hard stop in an emergency.

- Branch circuit fusing: Branch fuse protection maintains system functionality by isolating load elements in case of a power loss so the load bank can continue operating. Branch circuit fusing essentially eliminates system-wide load bank malfunction.

- Automatic load dump circuiting: The automatic load dump circuiting on the operator controls visually alerts the operator of which load steps have been removed. In a power loss, the operator can disconnect all load steps and remove the load from the source.

- Over-temperature protection: This protection feature alerts the operator if the cooling airflow is limited or cut off so that the load bank can continue to function. For example, if the ventilation system malfunctions, the over-temperature protection controls can protect the overall system.

- Resistive function: Radiator-mounted load banks are resistive banks. To dispose of the generated heat, resistor load banks must eliminate it through forced airflow, convection or water cooling. The exhaust airflow from the generator radiator performs this function.

- Reduce wet stacking: Load bank testing is an effective way to reduce the effects of wet stacking when generators run under lightly loaded conditions. By determining the power output of the generator, facility operators can increase output and minimize wet stacking. This solution leads to improved engine performance.

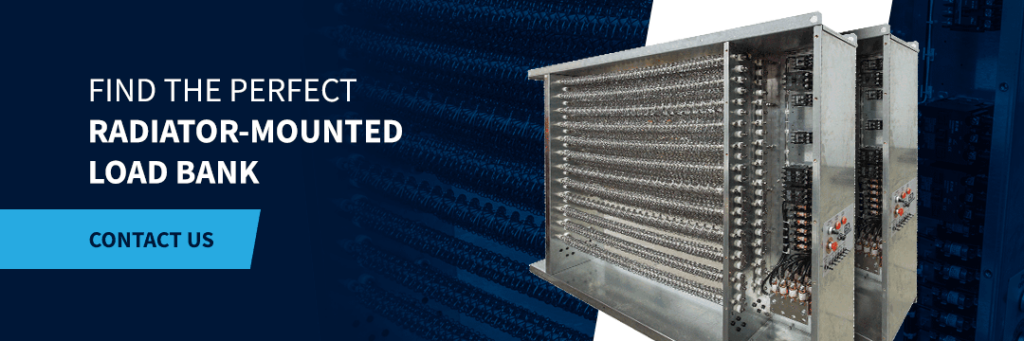

Find the Perfect Radiator-Mounted Load Bank

Radiator-mounted load banks are an excellent solution to protect your power source’s integrity and functionality. These highly efficient units can fit flexibly into many spaces and generator designs. Installing a radiator-mounted load bank on your diesel generator will provide your facility with efficient, cost-effective routine power testing.

If your facility needs a radiator-mounted load bank to test and support your power source, Load Banks Direct is your industry-leading load bank solution. We provide robust and compact load bank designs to fit our customers’ most challenging applications. With 20 years of manufacturing experience and a dedicated customer service team, Load Bank Direct is your complete load bank solutions provider.

Contact Load Bank Direct today.

We Are Here

To Help

Our team is here to support you and solve your power challenges. Connect with our responsive experts today to learn about our customized power solutions and products.